Description

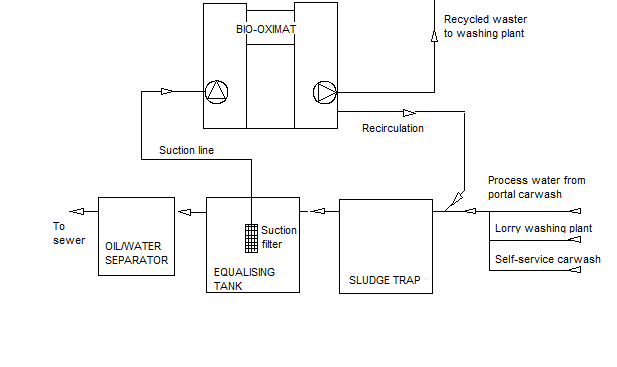

Operation

Within the BIO-OXIMAT the following physical, mechanical and biochemical processes are generated to realize optimal purification.

| Sediment separation | The impurities heavier than water settle down and are collected in the sludge trap. |

| Biological purification | Due to specially adapted microorganisms and saturation of oxygen the organic components in the water are degraded. |

| Flotation | The suspended solids are driven to the water surface by small air bubbles in the reaction vessel and then directed into the sludge trap system. |

| Filtration | The finest solid particles are eliminated from wastewater by a maintenance-free and self-cleaning filter. |

Due to the water current of the suction pump a depression is created within the air injector thus ambient air is injected into the water flow which is dispersed in water in the form of small bubbles. This intensive air injection in form of small bubbles is used for the following processes:

- flotation of suspended solids

- biological purification

- elimination of bad odours

- cleaning of the waste water filter module

Elimination of bad odours: The supply of oxygen to the wastewater prevents anaerobic degradation within the entire recovery system and eliminates any bad odours.

Technical datasheet

BIO-OXIMAT KP6

| Type BIO-OXIMAT KP6 | |

| Dimensions (lxwxh) | 1400 x 650 x 1780 mm |

| Capacity of process water

depends on equipment |

max. total 6 m³/h

4 m³/h with 3 bar supply depressurized 2 m³/h |

| Connected load | 2,2 kW, 400 V/50 Hz |

| Weight | approx. 180 kg |

| Type BIO-OXIMAT KP20 | |

| Dimensions (lxwxh) | 1800 x 650 x 1780 mm |

| Capacity of process water

depends on equipment |

max. total 20 m³/h

10 m³/h with 3 bar supply depressurized 10 m³/h |

| Connected load | 4,5 kW, 400 V/50 Hz |

| Weight | approx. 220 kg |

| Type BIO-OXIMAT KP30 | |

| Dimensions (lxwxh) | 1800 x 650 x 1780 mm |

| Capacity of process water

depends on equipment |

max. total 30 m³/h

15 m³/h with 3 bar supply depressurized 15 m³/h |

| Connected load | 5,5 kW, 400 V/50 Hz |

| Weight | approx. 230 kg |